-

Alumina Ceramic Components

-

Ceramic Housing

-

Metallized Alumina Ceramics

-

Custom Ceramic Parts

-

Alumina Ceramic Insulator

-

Alumina Ceramic Rings

-

Pressure Sensor Ceramic

-

Advanced Technical Ceramics

-

Advanced Engineering Ceramics

-

Fuse Ceramic

-

Ceramic Connector Blocks

-

Electronic Ceramic Components

-

Magnetron Ceramic

-

Zirconia Ceramic Parts

-

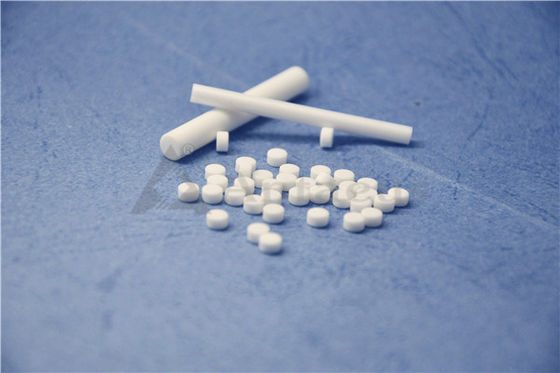

Alumina Ceramic Rods

-

Mr.FarnReply very fast and easy to talk!

Mr.FarnReply very fast and easy to talk! -

Mr.JacksonGood service and nice to talk.

Mr.JacksonGood service and nice to talk.

Machinable Aluminum Oxide Rod

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Alumina Ceramic Rods / Aluminum Oxide Insulation Rods For Battery | AL2O3 Content | 90% - 99% |

|---|---|---|---|

| Tensile | 30 Kpsi - 32 Kpsi | Flexural | 55 Kpsi - 60 Kpsi |

| Compressive | 300 Kpsi - 330 Kpsi | Density | 3.7 G/cc - 3.92 G/cc |

| Hardness | 13.8 HV, Gpa - 18 HV, Gpa | Thermal Conductivity | 25 W/(m K) - 32 W/(m K) |

| C.O.T.E | 75 In / In°C (x10^7) - 78 In / In°C (x10^7) | Working Temperature | 1500 °C - 1750 °C |

| Dielectric Constant | 9.5 - 9.8 | Volume Resistivity | >10^14 Ohm-cm |

| Dielectric Strength | 16 KV/mm - 20 KV/mm | ||

| Highlight | AL2O3 Aluminum Oxide Rod,Machinable Aluminum Oxide Rod,AL2O3 machinable ceramic rod |

||

Alumina Ceramic Rods / Aluminum Oxide Insulation Rods for Battery

1. Description:

Alumina, or aluminum oxide Al2O3, with a molecular weight of 102, is the major source of aluminium in nature. Al2O3 has very high melting point, which is 2,072 °C and it is extremely hard. Alumina ceramic is the most common technical ceramic material and relatively traditional material. High purity aluminum oxide ceramics as a fine ceramic material is widely used in a lot of industries. This material has superb performances in electrical insulation, high thermal conductivity, high chemical resistance, good wear resistance and low thermal expansion.

1) High hardness and high density

2) Low thermal conductivity

3) Chemical inertness

4) Good wear resistance

5) Lower medium spoilage

6) Stiffness texture

3. Material Features / Properties:

| Color | White or Ivory | White or Ivory | White or Ivory | |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics | ||||||||

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | Pass | - | |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | Pass | Pass | Pass | - | - | - | |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | ≤8 | - | |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - | |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | - | 4 | ||

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - | |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ | ||||||||

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - | |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - | |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - | ||

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - | ||

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - | |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Printing --- Nickel Plating --- Assembing --- Brazing --- Inspecting --- Packing

![]()

6. Application Fields:

Widely apply for new energy vehicles, charging piles, solar power generation, energy storage and power storage system, electric vehicle power system and so on.

![]()

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

![]()

8. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter

![]()

9.Order Flow Steps as belows: Inquiry ---Quotation --- Place an order --- Production --- Delivery

![]()

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service

![]()

11.Shipping and Package:

![]()

12. Our aimed market :

![]()

Notes:Above information only for reference and please contact with us for more details freely when you have any inquiry!